Product DescriptionThere is allots of waste plastic in environment such as PP, PE, LDPE, HDPE, ABS, after all this plastic waste collected they will be taken to Recycling plants. They will be separated. All the cleaned and dried material will go to Extruder machine, where bocomes a reusable Granule

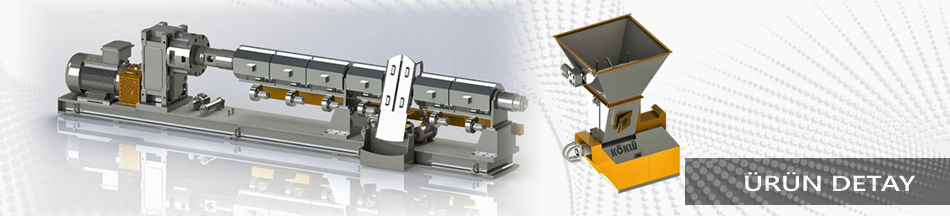

- Extruder will be designed according to material will be recycled. Between 100-100kg/saat and Screw diameter, screw length Ø90mm- Ø160 (Length/Diameter) ratio, venting zone, amount also will be designed according to Capacity and to material type.

- Screw and Barrel will be designed, depends on materials. Such as LDPE, HDPE, PP, PS, ABS

- Screw Barrel made of DIN-8550 and DIN-4140 material. Special bimetallic welding is applied on screw to lengthen the life-time of screw. Also heat treatment and hardening will be applied on screw and barrel.

- All the hazardous gas will be removed with based en European standarts designed ventilation system.

- Direct connection of Main Motor to Gearbox obtained energy consumption.

- Ceramic heaters, isolated covers and inverters helps electric saving and this also reduces the first operation time of the machine. It is also possible to keep different regions in different temperature level by the help of blowers on the heater

|